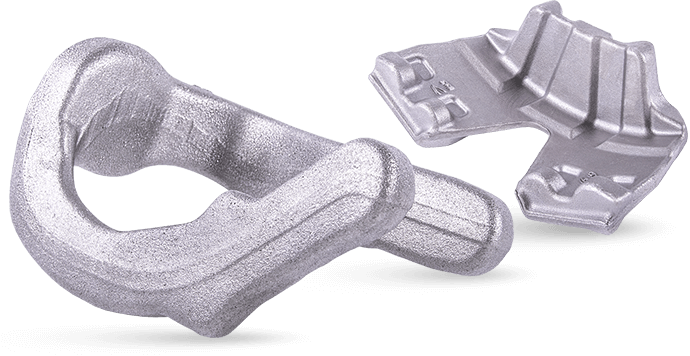

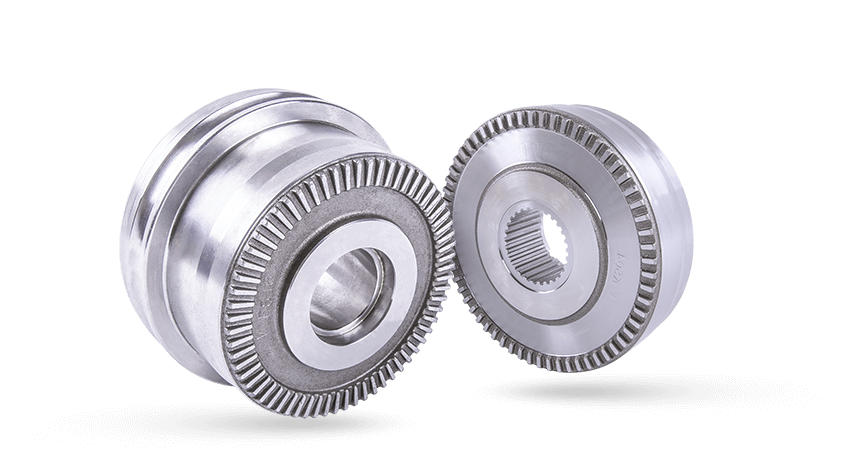

Transmissions and clutches

We develop and manufacture a wide range of forgings for transmissions and clutches in series of thousands up to millions of pieces for the automotive industry, as well as original forging for hybrid propulsion systems, and forgings for the specific conditions of cranes and forklifts.